Hydraulic cylinders are crucial components used in various industries, providing the necessary force and motion for numerous applications. Over time, these cylinders may undergo wear and tear, necessitating a rebuilding process to restore their optimal performance. In this article, we will provide a comprehensive step-by-step guide on how to rebuild a Hydraulic Cylinder, ensuring its longevity and efficiency.

Step 1: Disassembly

Begin by carefully removing the hydraulic cylinder from the equipment or machinery.

Securely hold the cylinder in a vise or suitable fixture.

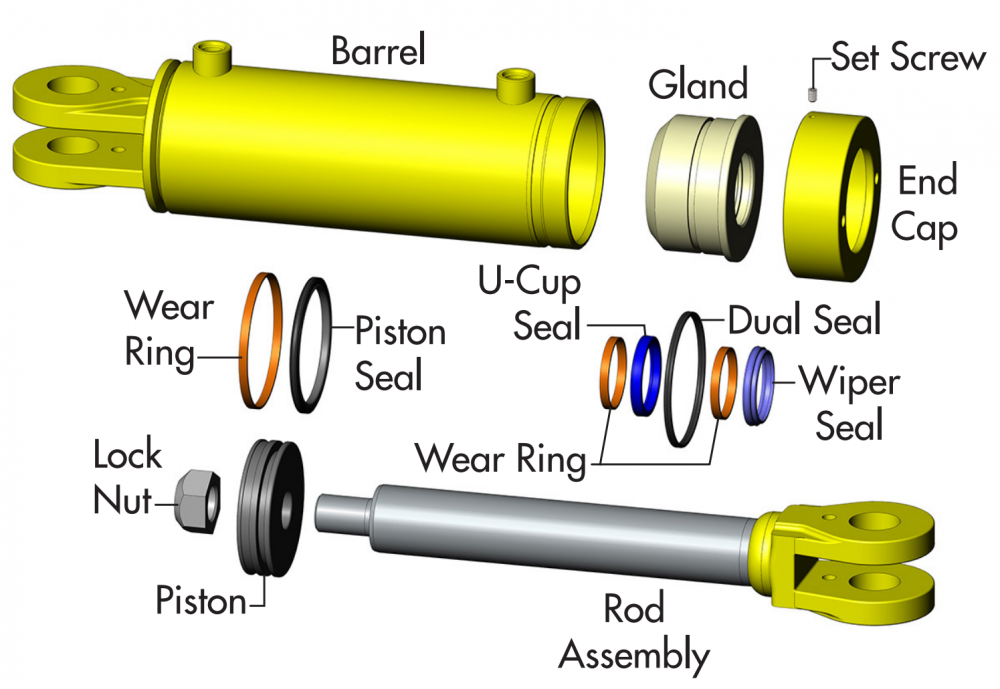

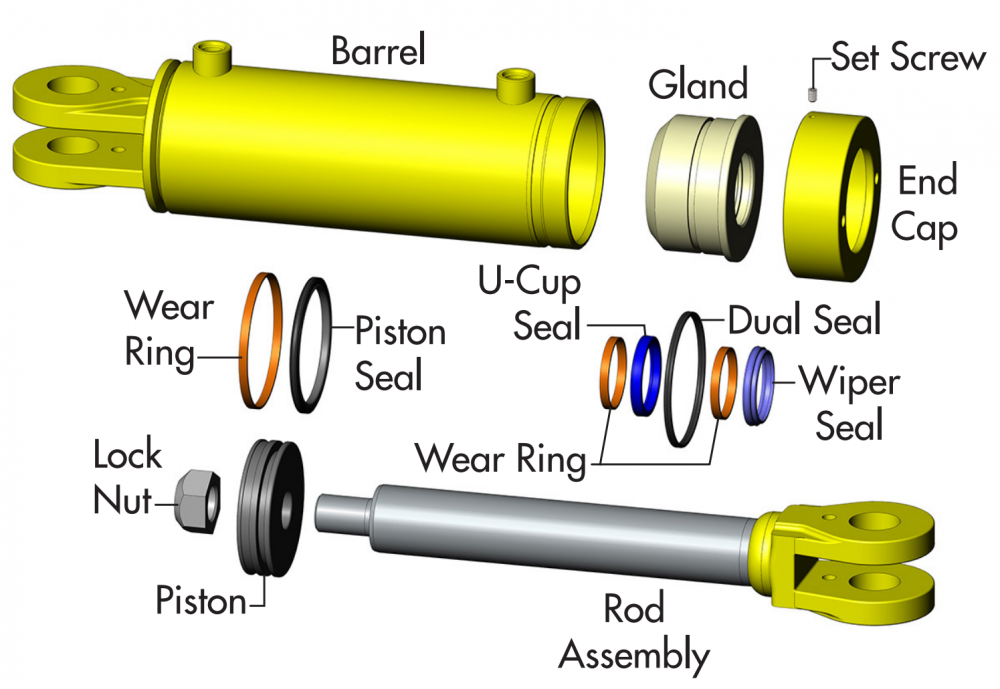

Gently disassemble the cylinder by removing the end caps, seals, and other components, taking note of their order and orientation for reassembly.

Step 2: Inspection and Cleaning

Thoroughly inspect all cylinder components for any signs of damage, wear, or corrosion.

Clean all parts meticulously using an appropriate solvent to eliminate dirt, debris, and hydraulic fluid residue.

Use a magnifying glass to inspect the cylinder bore and piston rod for scratches, scoring, or pitting. In case of significant damage, consider professional machining or replacement.

Step 3: Replacement of Seals and Components

Replace all worn or damaged seals, o-rings, and other components with compatible replacements suitable for the hydraulic fluid and operating conditions.

Prior to installation, apply a thin film of clean hydraulic oil to lubricate the new seals and facilitate their placement.

Step 4: Reassembly

Begin reassembly by carefully inserting the piston rod back into the cylinder bore, ensuring not to damage the newly installed seals.

Place the new seals and backup rings meticulously into their respective grooves in the cylinder bore and end caps.

Apply an appropriate thread sealant to the end cap bolts and tighten them following the manufacturer's recommended torque specifications.

Step 5: Testing and Reinstallation

Once the cylinder is reassembled, conduct a pressure test to identify any leaks or abnormalities.

Reinstall the hydraulic cylinder into the equipment or machinery, ensuring proper alignment and connection of hydraulic lines.

Gradually apply pressure and observe the cylinder's operation, verifying smooth movement without any leakage or excessive friction.

Conclusion:

By following these step-by-step instructions, you can successfully rebuild a hydraulic cylinder, thereby extending its lifespan and maintaining optimal performance. Regular maintenance and inspection are essential to promptly identify and address any issues. Always refer to the manufacturer's guidelines and seek professional assistance whenever necessary. With proper care, your hydraulic cylinder will continue to provide reliable force and motion in your applications.

To learn more about hydraulic products, visit our Hydraulic Hose and Hydraulic Fittings.